Hearing Aids are Truly Unique—from an Audio Test Perspective

Hearing aids are truly unique from an audio test perspective being one of the few audio devices that has both acoustic input and output. With even the simplest ones, hearing aids include microphones, a power amplifier, digital signal processor, loudspeaker and controls integrated into a tiny, battery-powered package. Add in optional features like noise reduction, microphone arrays/beamforming, telecoils, wireless connectivity, remote control, variable DSP programs, direct audio input and synchronization between left and right sides, and things can get interesting.

Industry Standards

For air conduction hearing aids, key audio test standards include American Standard ANSI/ASA S3.22, Specification of Hearing Aid Characteristics, and Parts 0 and 7 of the IEC 60118 series of international standards, Electroacoustics – Hearing Aids. The IEC 60118-7 series is nearly identical to ANSI/ASA S3.22; both standards are intended for production test of hearing aids covering the frequency range from 200 Hz to 5 kHz. Part 0 of the IEC 60118 series specifies many of the same tests as IEC 60118-7 and ANSI/ASA S3.22, but it covers a wider frequency range (200 Hz to 8 kHz), and it is intended more for R&D applications. These R&D applications can include developing specifications for a new hearing aid model or qualifying a model of hearing aid for sale in a country or regional jurisdiction.

Test Requirements

Tests specified in the ANSI/ASA and IEC hearing aid test standards are typically part of the feature set available in audio analyzers. For example, hearing aids require frequency response measurements at different gain settings, noise level measurements and Total Harmonic Distortion (THD) measurements – all standard measurement features for a good audio analyzer. But there are some aspects of the tests that require special features, or unique results.

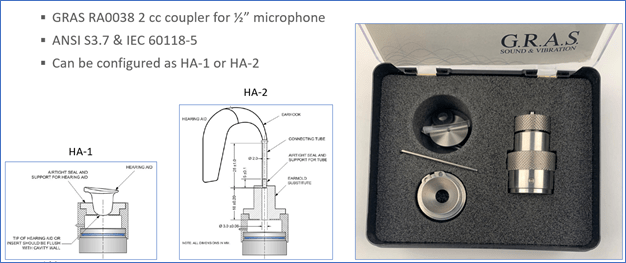

The acoustic input and output nature of hearing aids does offer some challenges. To measure hearing aid output, a special 2 cc acoustic coupler (like the one shown in Figure 1) is required, with a pressure-response measurement microphone. The audio analyzer must also be able to account for the microphone sensitivity, and to display measurement results in acoustic units (Pa or dBSPL).

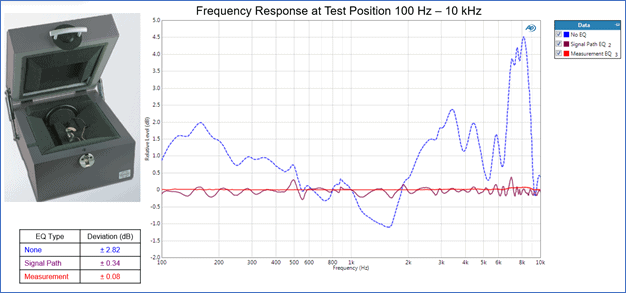

To apply acoustic input signals to hearing aids, the audio analyzer must be able to drive a loudspeaker at a known sound pressure level over a wide frequency range. Even the best loudspeakers have a non-flat frequency response, and their sensitivity can drift with time. As such, it’s important to have a means to “calibrate” the loudspeaker’s output and to equalize it to have a flat response.

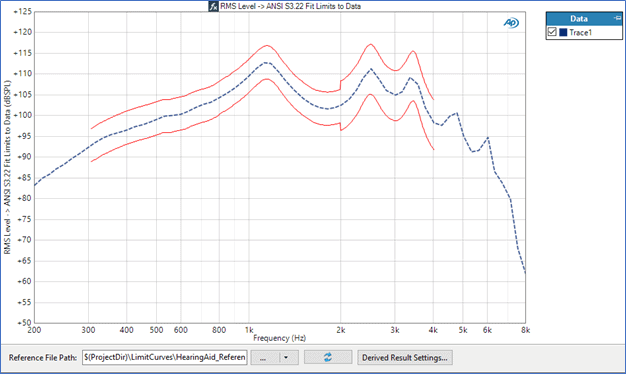

ANSI S3.22 Fit Limits to Data

One of the new hearing aid-specific features is the “tolerance method for frequency response” used to construct limits for measured frequency response curves. ANSI/ASA S3.22 and IEC 60118-7 specify that frequency response limits are constructed based on a reference curve for the model of hearing aid being tested. Limits are offset from this curve by ±4 dB in a low-frequency range (up to 2 kHz) and by ±6 dB in a high-frequency range (above 2 kHz). Interestingly, the standards suggest the use of a transparent overlay with the limits drawn at the same scale as the measured frequency response of a unit. The limits may be shifted not only in the vertical direction (along the level axis), but also horizontally, by up to ±10% along the frequency axis, until the measured curve is centered within the limits.

Since transparencies have gone the way of the dinosaur, these special limits are now constructed and best fit to the data algorithmically.

New IMD Measurements for Hearing Aids

AP audio analyzers have had a variety of built-in Intermodulation Distortion (IMD) measurements since the System One was first introduced over 35 years ago. However, the IMD measurements specified in ANSI/ASA S3.22 and IEC 60118-0 are slightly different from the IMD measurements typically used for audio test. Both standards call for a type of IMD measurement known as Difference Frequency Distortion (DFD) with a difference frequency of 125 Hz. However, specifications such as the swept frequency range, distortion products included, and results displayed are slightly different between the two standards and different from other DFD measurements.

With historical testing accuracy, AP audio analyzers guarantee all the unique features of hearing aids are thoroughly and rightfully tested to meet industry and worldwide standards.