From Frustration to Automation: How APx500 Software Transforms Audio Testing

A Turning Point for Sarah

In the realm of production testing, consistency, and efficiency are key to success. Meet Sarah*, an engineer responsible for establishing the audio test routines at her company. The company handles large volumes of returned earbuds made by various manufacturers, determining which devices are damaged and which are suitable for resale.

To Sarah’s dismay, a recent statistical analysis revealed that many of the earbuds deemed to be in working condition had been returned after resale for issues relating to audio performance. Faced with the challenge of reducing these “test escapes,” Sarah began to recognize the drawbacks of their subjective testing process, in which human operators were asked to evaluate each pair of earbuds through a set of listening tests.

Determined to find a more objective and repeatable solution, Sarah discovered Audio Precision’s APx500 measurement platform. After reaching out to her local sales representative to procure equipment for evaluation, Sarah worked with the Audio Precision (AP) Global Support Team to develop a test sequence that prompts the operator to select an earbud model and mount the earbuds on the test fixture. A series of objective audio tests are then automatically run, with the results compared to objective limits, and the measurement results saved for later statistical analysis. After a trial run on the production floor, Sarah was delighted to find that the new test system was not only more reliable in identifying genuine issues with the devices, but also significantly faster than the previous subjective tests.

In this blog post, you will learn about the automation capabilities of APx500 and discover how it can revolutionize your audio testing and analysis processes, just as it did for Sarah.

"We test a large quantity of Bluetooth® audio devices. In a manual testing context, this is a laborious process with unreliable results. The primary draw to purchasing and using the APx systems was the ability to control and automate many of the elements required by the process. To put it succinctly, the APx system allows us the ability to tightly control all aspects of the testing process, reduce operator touch times and remove subjectivity from the results. I give accolades to the software team at AP, as they have created UI\UX that is easy to understand, despite the massive number of parameters, tests, and feature sets that can be configured. I am not an audio engineer nor is this sector within my wheelhouse. The equipment landed on our docks, we immediately started to develop and integrate our application to better fit our production needs and within seven business days, we had a viable production station. The station is running reliably, adding value to our business and our customers. I give much of the credit to the APx500 / APx500 API documentation.”

– John M. at Reconext

APx500: The Unified Platform for APx Audio Analyzers

Before we can discuss the automation capabilities of APx500, it is important to understand what the APx software is and what it can do. APx500 is a powerful and versatile audio measurement software platform designed by AP, serving as a common software platform for all APx audio analyzers. Widely used by audio engineers, researchers, production line operators, and manufacturers, APx500 streamlines complex audio testing processes by providing a comprehensive and intuitive solution for testing and analyzing audio devices and systems.

The APx500 software provides two user interfaces: a robust graphical user interface (GUI) for hands-on interaction, and an extensive Application Programming Interface (API) that enables advanced automation, integration, and customization.

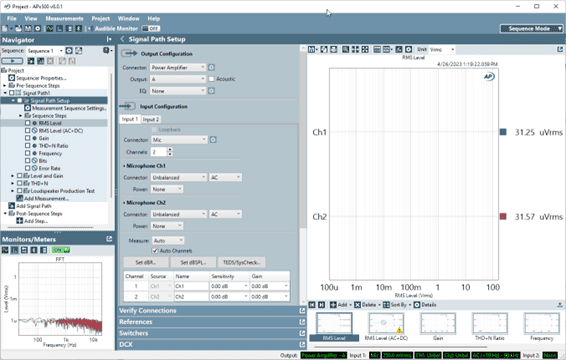

The APx500 software GUI

Three Development Strategies

When automating measurements using APx500, there are three development strategies to consider. Selecting the right approach from the outset can help save time and effort.

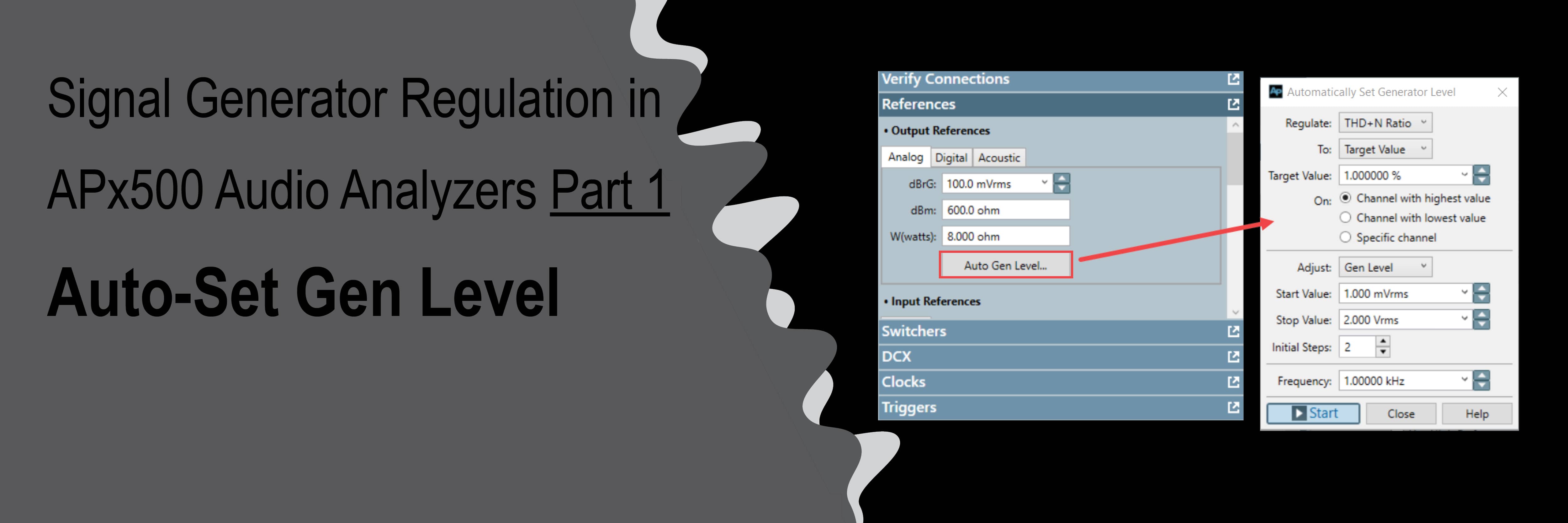

- Using the Built-in Sequencing Capabilities

The first strategy involves using the GUI with its built-in sequencing capabilities without employing the API. Built-in features include:

- Measurement sequencing

- Operator prompts (with optional images)

- Automated Level Setting

- Upper and lower data limits with pass/fail analysis.

- Automatic data export

- Report generation

- Appending statistics to a log file

- Control of auxiliary devices

- A simplified Production Test mode

- And more

In most cases, when helping customers to automate their measurements, we will recommend this strategy as it requires no code development, maintenance, or programming experience, and is the fastest to implement. However, this is only a viable option if the built-in features meet all your requirements. Please consult Technote 129 for a more complete overview of the GUI with its automation-related features.

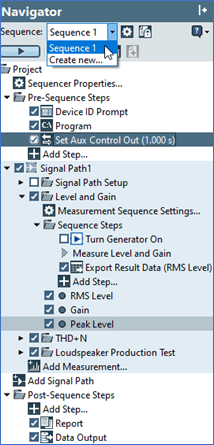

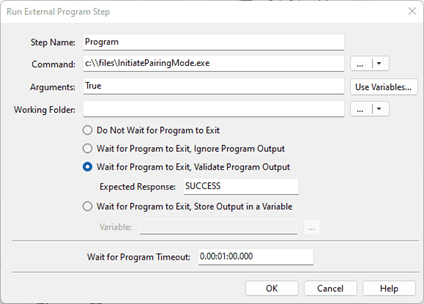

An example measurement sequence

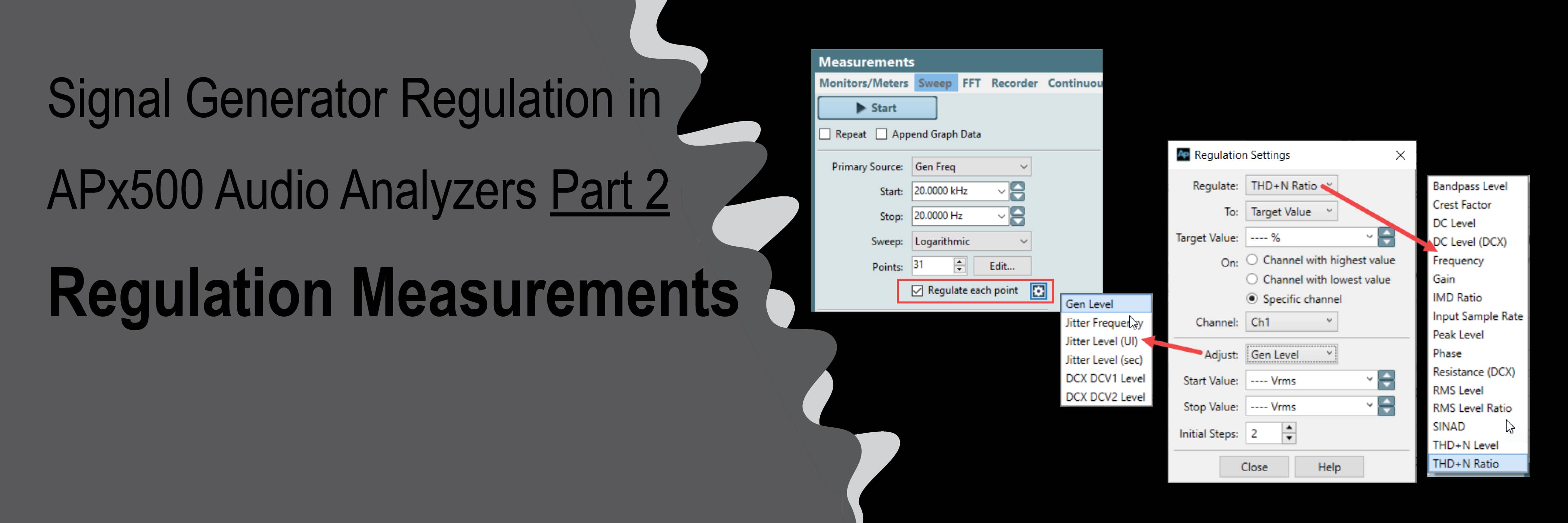

- Using the Built-In Sequencing Capabilities with Program Steps

The second strategy builds upon the first but incorporates the added functionality of Program sequence steps. Program steps enable the execution of custom scripts (e.g., .exe, .bat, or .py using the Python interpreter) within a sequence, allowing you to write and run a program that, for example, puts a Bluetooth device into pairing mode or queries a connected device for information. This approach is useful in situations where the built-in features satisfy most needs, but some custom scripting is needed.

An example of a program step configured to put the connected DUT with its Bluetooth radio into pairing mode

- Writing a Custom API Program

The third strategy involves writing a fully custom API program that controls the APx500 software and the connected analyzer. With this approach, all the software’s capabilities can be automated or sequenced in ways that are not natively supported via the GUI, and the APx software can be hidden if needed. The software has built-in measurement sequencing capabilities that can still be used; however, these features are now accessed programmatically rather than manually. This offers much greater flexibility than the first two strategies but will require additional time to identify API commands and create, debug, and maintain the API program.

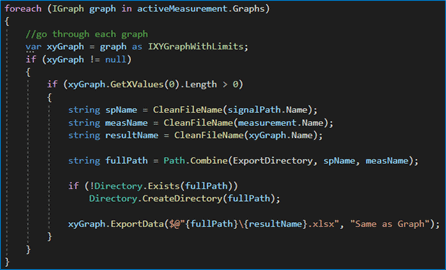

Many of the commands available in the API closely resemble the naming and structure of the graphical interface

Examples of API programs include an app for testing headphones according to a specific standard, a script that exports all data in a project file to disk, a continuously running script that logs a measurement to a database periodically, and a production test controller app that communicates with test hardware and logs measurements to a database.

What is the API, anyway?

The APx500 API is a collection of commands and functions that allows developers to interact with the APx500 measurement software programmatically. Built on .NET and utilizing an object-oriented approach, the API is designed to be versatile and user-friendly. It supports any language with a Microsoft .NET interface including C#, Visual Basic, C++, MATLAB, Python, and LabVIEW, making it accessible to a wide range of developers and applications. Through the API, you can control all the settings, measurements, and capabilities of the GUI, enabling you to fully harness the power of the APx500 software in your custom applications.

An excerpt from an API script that exports all XY graph data to the file

When Should I Use the API?

The APx500 API is a versatile tool that can be utilized in various situations. Some common scenarios in which you might want to use the API include:

- Automation of repetitive tasks: If you need to perform repetitive tests, the APx500 API can be used to automate them, saving you time, and reducing the potential for human error.

- Integration: The APx500 API can be used to integrate your audio tests with other systems, applications, and databases.

- Customization: The APx500 API provides you with the flexibility to create custom solutions tailored to your specific requirements. Whether you need to implement unique test methodologies, create custom calculations, or design a specialized user interface, the API allows you to leverage the APx500 software in ways that best suit your needs.

Conclusion

The APx500 software is a powerful tool that offers users the flexibility and control needed to automate, integrate, and customize their audio testing processes in a wide array of scenarios. By understanding the capabilities of the APx500 software and its API, you can leverage them to streamline your workflows, enhance productivity, and create custom solutions tailored to your specific requirements – not only for users in production tests like Sarah, but for any application where automation provides an advantage.

For more information about the automation-related features in APx500 software, please refer to Technote 129.

For information on the API, read the Introduction to Programming the APx500 API included with the API Developer Tools, also available on www.ap.com.

For further information or assistance, contact the AP Global Support department at [email protected].

Contact us to learn more about APx500 Software and its capabilities.

Subscribe today to access our complete portfolio of content including on-demand webinars, technical notes, application notes, and more. Or visit ap.com to learn more about our products and how AP can assist you with your test and measurement needs, from R&D to the production line.

*Sarah is a composite character illustrating real-world scenarios encountered by the AP Global Support Team.