Using Sound Cards for Audio Measurement

With the introduction of APx500 Flex, Audio Precision is making it possible to use APx500 software with a third-party audio interface. To many, this might seem like a surprising change. AP established itself by making the world’s finest, hardware-based audio analyzers. To this day, AP manufactures the highest performance, and the most robust and reliable audio measurement instruments available – a fact of which we are obviously quite proud. In that context, why is AP embracing the idea of using third-party audio interfaces (what some call “sound cards”, owing to their legacy of discrete add-in circuit boards installed inside computer chassis such as the original Creative Labs™ SoundBlaster®)?

APx500 software has supported the use of third-party ASIO audio interfaces since version 4.2. This was originally added at the request of manufacturers of these devices who wanted to be able to easily test them. Since then, we have built on the ASIO interface as a bridge to other interfaces, such as Automotive Audio Bus®(A2B), developed by Analog Devices™, Dante™ and the Dante Virtual Soundcard® or Focusrite RedNet PCIe® sound card, and Soundwire™ MIPI Interface®. In these contexts, we have already seen customers who were using ASIO for input and output, and for whom the hardware analyzer often became just a large and superfluous dongle. So, for many customers, APx500 Flex is simply a natural progression to how they were already using our audio measurement software.

However, the core observation remains. With APx500 Flex, we are undeniably proposing that sound cards are good enough for audio measurement. This is a shift for us. That shift is driven by our acknowledgement of a ground truth. Many audio measurements do not require the exceptionally low self-noise, high input voltages, or vanishingly small distortion available from APx hardware analyzers. For example, to conduct quality control of speakers on a manufacturing line, you typically need to make measurements from about 80 to 114 dBSPL. With typical measurement microphone sensitivities, you do not need to acquire input signals much higher than 1 Vrms in amplitude. You do not need the 230 Vp maximum input of an APx555 audio analyzer. Many factories will have 80 dBSPL of ambient noise and setting that aside, the self-noise of a typical measurement microphone system will easily be 40 or more dB above the ~1 µVrms self-noise of the analyzer. Meanwhile the distortion of a good speaker is often in the range of 1% (-40 dB) to perhaps 0.1% (-60 dB), making the residual distortion figures for an APx hardware analyzer (< 0.0001%, -120dB) seem absurdly good by comparison.

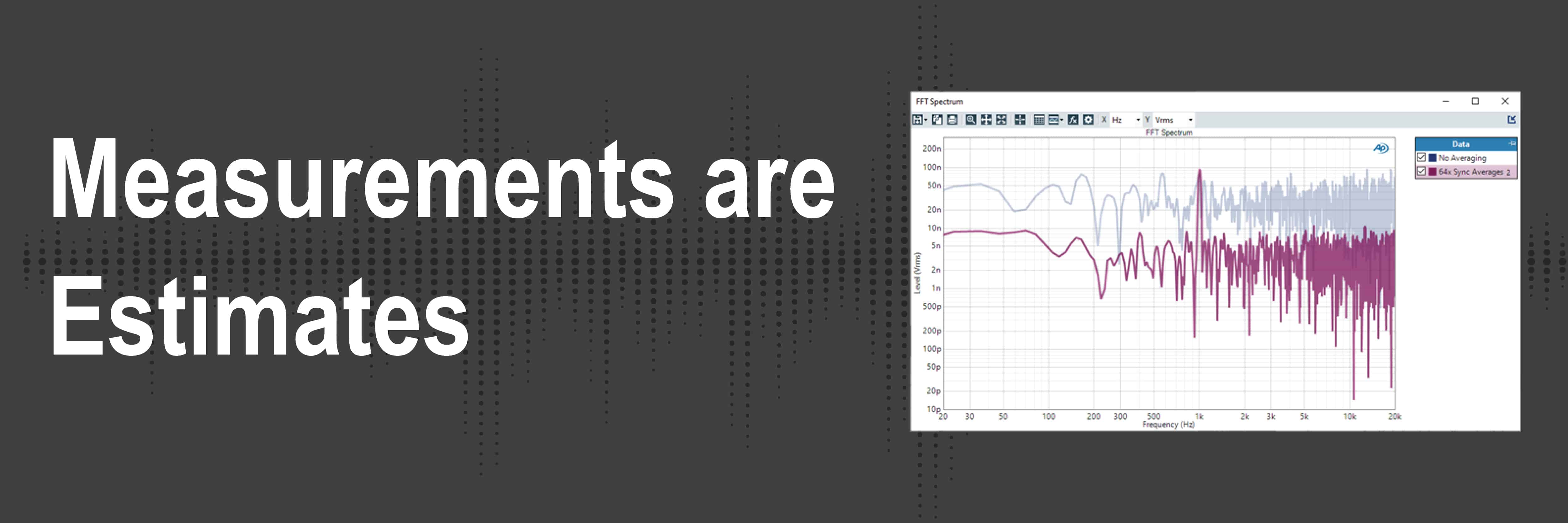

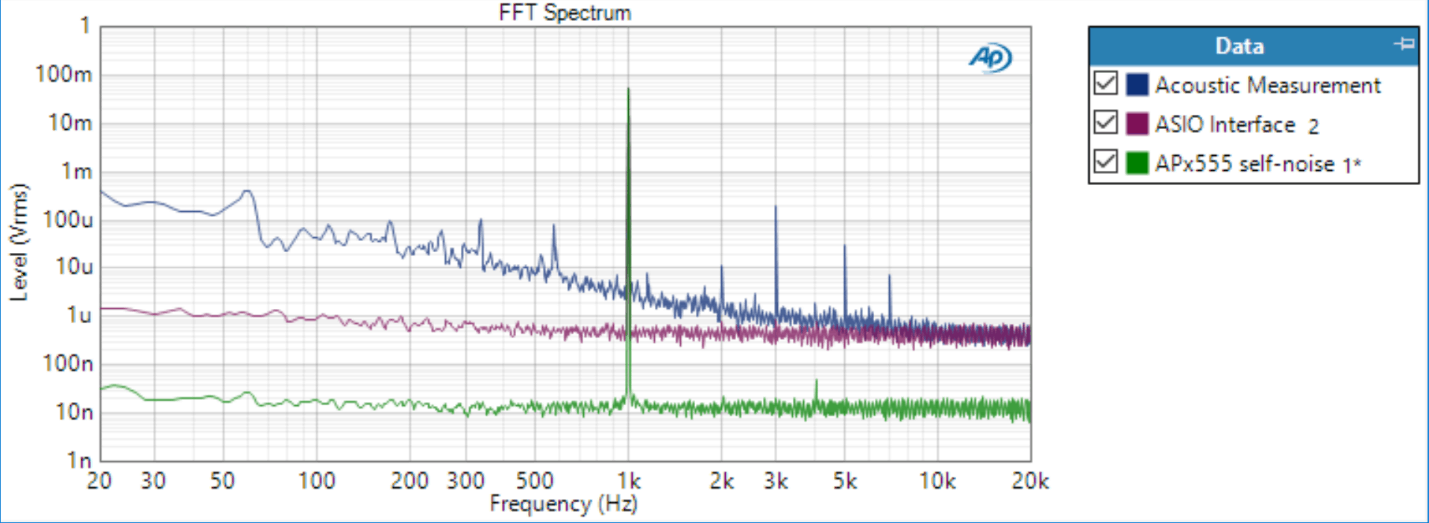

Acoustics Measurement vs ASIO Interface Residual vs APx555 Residual

As an example, the graph above compares the FFT spectra of three signals in Vrms:

- The output from a microphone with 50 mV/Pa sensitivity exposed to a loudspeaker generating a sine signal of 1 Pascal in magnitude at 1 kHz frequency.

- The residual noise and distortion of a high quality ASIO audio interface measuring the equivalent voltage (50 mVrms) of a pure sine signal.

- The residual noise and distortion of an APx555 audio analyzer measuring the same 50 mVrms sine signal.

With this microphone sensitivity, the acoustic background noise in the environment (a typical office space), creates about 1 mV of noise. The speaker has very significant distortion, and with the background noise added in, results in a THD+N of just -36 dB. The ASIO interface has a self-noise of 28 µV and with a 50 mV stimulus its residual THD+N is -65 dB. Finally, the APx555 has a self-noise of roughly 840 nVrms and with the same 50 mV stimulus, its residual THD+N is about -96 dB.

In short, while the APx555 has a self-noise 50 dB lower than the ASIO audio interface, the audio interface is still more than 30 dB quieter than the acoustic background noise. This provides more than enough headroom to make measurements on the speaker in question.

AP was founded five years before the first personal computer sound card was shipped. That device, the Creative Labs™ SoundBlaster® was based on a mono 8-bit converter, and it would have been absurd to use it for audio measurement. In our founding era, using anything except dedicated measurement hardware was simply not an option. However, in the ensuing 35 years a lot has changed. Today high-quality DACs and ADCs have provided for audio interfaces with surprisingly low-price points that rival our original audio analyzer, the System One. With APx500 Flex we are providing our customers the ability to choose a balance between price and measurement capability.

No, you can’t use a sound card to measure a high-power amplifier or low-noise and distortion DACs, ADCs, or many other devices. But yes, an ASIO audio interface or sound card can have enough capability to measure a speaker, microphone, or headphone. The physical test requirements of these devices simply do not require all the fidelity, dynamic range, and ancillary features that an APx hardware analyzer can provide. For more demanding applications—where requirements can include challenging performance specifications, a need for calibrated and/or high-reliability hardware, specialized digital I/O options (e.g., Bluetooth™ headphones), or unique, hardware-dependent measurements like jitter—APx500 B Series audio analyzers remain the best choice for developers, design engineers and test technicians everywhere.